Technical Information

Propionic acid, butyric acid secondary mother liquor turn waste into treasure

Application for invention patent certificate in 2022.

2023/03/14

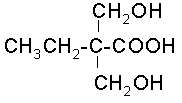

2,2-dimethylol butyric acid is a kind of both hydroxyl and carboxyl groups, it can also be used in leather materials, liquid crystal, ink, food additives and adhesive chemical industry, etc., especially in the manufacture of water emulsion polyurethane and leather finishing agent, it is not only a chain extender, but also can make polyurethane obtain good self emulsification performance, can greatly improve the stability of polyurethane water emulsion.

2019/11/11

Preparation of Waterborne Polyurethane by DMPA Amination Process

Author: Li Qingxi, Kong Xia, Zhu Yanan, Qu Quanqing (School of Chemistry and Chemical Engineering, South China University of Technology, Gabriel Chemical Group Co., Ltd.) Abstract: Polyurethane aqueous dispersion (PUD) without N-methylpyrrolidone (NMP) and organotin was successfully prepared by aminating dimethylol propionic acid (DMPA) as a hydrophilic chain extender. The effect of amination process on PUD preparation process and dairy performance was studied, the structure and properties of the film were characterized. The results show that: (1). The use of DMPA amination process can avoid the use of NMP and organotin catalysts, and prepare organotin-free, NMP-free waterborne polyurethane dispersions; (2). The performance of waterborne polyurethane film prepared by amination, especially water resistance and other chemical resistance, is better than that of PUD catalyzed by organotin; (3). The process is simple and has the advantage of environmental friendliness. (Source "2012 Waterborne Polyurethane Industry Annual Conference Proceedings")

2019/09/20

Comparison of main properties of DMBA and DMPA polyurethane emulsion

Authors: Zeng Jun, Wang Wusheng, Ruan Deli, Zhong Feng (Anhui University Applied Chemistry Research Center, Anhui University Kezhao Fine Chemical Factory) Abstract: This paper uses DMBA and DMPA as hydrophilic monomers to prepare polyurethane emulsion, compares their emulsion and film properties, and discusses the reasons, so as to provide reference for industrial production. The test passed the following performance comparisons: 1. Comparison of the solubility of DMBA and DMPA In the experiment, it was found that the dissolution behavior of DMBA and DMPA in polymer polyols was less affected by the relative molecular mass of polymer polyols, but the dissolution temperature of the two was very different. The dissolution temperature of DMPA is 145~150 ℃, below this temperature, and slowly precipitation, while the dissolution temperature of DMBA is 80 ℃, once dissolved, reduce the temperature without precipitation phenomenon. This is due to the lower melting point of DMBA (= 108-113°C) and the higher melting point of DMPA (= 175-188°C). 2. Performance Comparison of Polyurethane Emulsion DMBA and DMPA polyurethane emulsions are characterized by solid content, pH, viscosity, thermal stability and emulsion appearance. The results are shown in the following table: scheme number, solid content (%), pH viscosity (mPa.s), thermal stability (60 ℃× 72h), emulsion appearance A- 10A-15A-2025.225.125.48.18.28.44.25.15.7, no gel, no gel, no gel white, A small amount of precipitated translucent transparent blue B- 10B-15B-2025.325.225.08.28.38.44.46.06.2 does not gel, does not gel, does not gel, does not gel Milky White translucent transparent blue note: a and B represent DMPA and DMBA respectively; 10, 15 and 20 respectively represent carboxyl content of 1.0, 1.5 and 2.0 respectively; Formula: hard segment content is 48%. 3. Comparison of reactivity between 3.DMBA and DMPA; 4. Comparison of mechanical properties of polyurethane emulsion film; 5. Comparison of water resistance, chemical resistance and low temperature resistance of polyurethane emulsion film; Through the above performance comparison, it is believed that 2,2-dimethylol butyric acid has the following characteristics: (1) The dissolution temperature in polyether or polyester polyol is relatively low, generally about 80 ℃, and has nothing to do with the relative molecular mass of polymer polyol, it is convenient for homogeneous reaction; (2) The reaction time of polyurethane in DMBA system can be shortened by experiment and infrared spectrum analysis; (3) The polyurethane film prepared by DMBA has high strength and high elasticity.

2019/09/20

Synthesis and Properties of Solvent-free Waterborne Polyurethane

Authors: Liu Dubao, Tang Deng, Zhang Wenrong, Xu Gewen (Anhui University College of Chemistry and Chemical Engineering, Anhui Key Laboratory of Green Polymer Materials) Abstract: The solvent-free waterborne polyurethane resin was synthesized by prepolymer method using dihydroxymethyl butyric acid (DMBA), isophorone diisocyanate (IPDI), polyoxypropylene glycol (PPG-220) as the main raw materials, and compared with WPU synthesized by DMPA. The effects of R value, type of chain extender and amount of chain extender on the performance of PU emulsion and coating film were discussed, and the synthesis process was studied, and the product was characterized by DSC thermodynamic analysis and infrared spectrum, and the ATR infrared spectrum of the adhesive film showed the typical infrared characteristics of water-based polyurethane. Research conclusions: (1). In the process of synthesizing waterborne polyurethane with DMBA, the whole reaction process can be completed without adding a little solvent, and the reaction result conforms to the formula design. (2). When designing the formula, the R value is above 1.3, the resin can be emulsified, and the synthetic waterborne polyurethane emulsion has a good appearance, excellent mechanical properties of the adhesive film and good medium resistance; (3). NCO conversion test can clearly see that the one-step NCO conversion rate is higher than the two-step NCO conversion rate, and whether it is one-step or two-step method, the whole reaction time only needs 5h to make the NCO conversion rate reach more than 98%; (4). The use of post-chain extension process can reduce the viscosity of the prepolymer during emulsification, increase the mechanical strength of the film than EDA, and the breaking elongation rate is smaller than EDA; (5). The waterborne polyurethane synthesized by DMBA can complete the reaction without or with little solvent, which greatly reduces the pollution of the solvent to the environment, reduces the potential safety hazard of the factory, reduces the difficulty of removing the solvent, reduces the cost of the whole production, and increases the competitive advantage of the market. (Source: Journal of Anhui University, Natural Science Edition, Vol.32, No.5, September 2008)

2019/09/20

Carboxylic acid type hydrophilic chain extender DMBA and DMPA

1. Introduction In the production of waterborne polyurethane, carboxylic acid, as an anionic hydrophilic chain extender, is a class of carboxylic acid with diols, which has been widely used for its unique molecular structure and excellent product performance. The carboxylic acid type chain extender mainly includes 2,2-dimethylolpropionic acid (DMPA) and 2,2-dimethylolbutyric acid (DMBA), which is a unique multifunctional hindered diol molecule with both hydroxyl and carboxyl groups; increase the alkali solubility of the coating. Can be applied to water-soluble polyurethane systems, water-soluble alkyd resins and polyester resins, epoxy ester coatings, polyurethane elastomers and powder coatings. It can also be used in leather materials, liquid crystal, ink, food additives and adhesive chemical industry, etc., especially in the manufacture of water emulsion polyurethane and leather finishing agent, it is not only a chain extender, but also can make polyurethane get good self emulsifying performance, can greatly improve the stability of polyurethane water emulsion, so it is widely used. 2. Advantages of Using Dimethylol Carboxylic Acid Aqueous Polyurethane Emulsion Generally, a hydrophilic agent is introduced into the polyurethane molecular chain, then neutralized with alkali to form a salt, and dispersed in deionized water by mechanical stirring to form an aqueous polyurethane emulsion. Applied to waterborne polyurethane hydrophilic agent mainly has three types of anion, cation and non-ion. Anionic type mainly includes: 2,2-dimethylol propionic acid, 2,2-dimethylol butyric acid, tartaric acid, sulfonic acid butanediol, sodium ethylenediamine ethyl sulfonate, half ester synthesized from glycerol and maleic anhydride, etc. Cationic type mainly includes methyl diethanolamine, triethanolamine, etc. Non-ionic type mainly includes hydroxyl-terminated polyethylene oxide. Non-ionic hydrophilizing agents, such as polyethylene oxide, must be present at high levels to stabilize the dispersion. Waterborne polyurethane resin made of hydroxy polyoxyethylene ether as hydrophilic group has good electrolyte resistance, but the film forming water resistance is extremely poor, so it is not practical. Cationic hydrophilic agent such as ethylenediamine sodium acrylate adduct as hydrophilic compound makes the whole reaction system alkaline, not only has the rapid reaction of-NH2 group and-NCO group, but also has the reaction of-NCO and-NHCOO-, so the reaction is difficult to control and easy to gel, and the emulsion particles made of coarse, film-forming water resistance is poor, and therefore can not be used in industry; anionic dimethylol carboxylic acid itself contains two hydroxyl groups, but also play the role of chain extender, this dual role in the preparation of self-emulsifying PU emulsion showed great superiority. In the process of carbamate synthesis, it makes the reaction system acidic. Under acidic conditions,-NCO and-OH react mildly, while-NHCOO-does not participate in the reaction and will not cause gel. In addition, dimethylol carboxylic acid also acts as a chain extender, so that the hydrophilic group (I. e. carboxyl group) is located in the macromolecular chain segment, and the tertiary amine can be used as a neutralizing agent to make excellent stability and excellent water resistance and solvent resistance of the film. Waterborne polyurethane resin. Dimethylol carboxylic acid is the best hydrophilic compound widely used in the preparation of waterborne polyurethane resins. 3. 2,2-dimethylol propionic acid (DMPA) and 2,2-dimethylol butyric acid (DMBA) Among the two dimethylol carboxylic acids, 2,2-dimethylol propionic acid has been used earlier and is currently a more common hydrophilic chain extender. Although it has many advantages, it still has many disadvantages, mainly its own high melting point (180-185 ℃), it is difficult to heat melting, which requires the addition of organic solvents such as N-methyl pyrrolidone (NMP), N.N-dimethyl amide (DMF), acetone, etc., and NMP has a high boiling point, it is difficult to remove after the preparation of APU. Moreover, the solubility of DMPA in acetone is small, and a large amount of acetone needs to be added in the synthesis process, which not only wastes energy but also brings security risks. Therefore, the use of 2,2-dimethylol propionic acid not only produces high energy consumption, but also easily causes organic residues in the product. 2,2-dihydroxymethyl butyric acid is a new type of hydrophilic chain extender which has emerged in recent years. 2,2-dimethylol butyric acid has the following main advantages compared with 2,2-dimethylol propionic acid: 1. better solubility in organic solvents. The following table shows the solubility data of DMBA and DMPA in different temperatures and solvents. Solubility data of DMBA and DMPA in different temperatures and solvents: serial number temperature ℃ acetone methyl ethyl ketone methyl isobutyl ketone DMBADMPADMBADMPADMBADMPA 12015170.420.1240442140.870.5 solubility: unit g/100g solvent solubility in water: DMBA 48%,DMPA 12%. 2. The reaction rate is high, the reaction speed is fast, and the reaction temperature is low. For example, the reaction time for synthesizing polyurethane prepolymer is short, generally only 50-60 minutes, while DMPA takes 150-180 minutes. 3. It is used for waterborne polyurethane emulsion with finer particle size and narrow distribution. 4. Low melting point, 108~114 ℃; 5. The diversity of formulations can reduce the use of solvents, thus reducing the cost of solvents and waste liquid treatment. 6. It can be used to prepare completely solvent-free polyurethane and polyester systems; in the actual synthesis process, it does not need to consume a little solvent, and the emulsion has good performance and excellent mechanical properties of the adhesive film, which not only shortens the reaction time, reduces energy consumption, but also saves energy. Therefore, 2,2-dimethylol butyric acid is currently known to have the best performance of hydrophilic compounds, industry experts believe that dimethylol butyric acid is a green chemical that will replace dimethylol propionic acid. The development of 4. dimethylol carboxylic acid in China The development and production of 2,2-dimethylol propionic acid in China started late. This is mainly restricted by the process of waterborne resin in China. China started the industrial production of 2,2-dimethylol propionic acid in 1995. In the 21st century, the demand for 2,2-dimethylol propionic acid increased year by year, and formed a certain market scale. However, it is a pity that the production of 2,2-dimethylol propionic acid in my country has not formed a scale so far. There are few manufacturers still producing 2,2-dimethylol propionic acid, and the production scale is relatively small. At present, my country's use is mainly dependent on imports. Because of its complex production process, difficulty in industrialization, high production cost, high price and serious environmental problems, the production development and application of 2,2-dihydroxymethyl butyric acid are greatly restricted. The production of 2,2-dimethylol butyric acid in China began in 2006. There are only a few manufacturers, but all of them have been shut down one after another due to the above reasons. As a result, there is no 2,2-dimethylol butyric acid available in China in recent years, resulting in many water-based material manufacturers crying for food. They are eager to change this passive situation as soon as possible and hope to use 2,2-dimethylol butyric acid as soon as possible. Jiangxi Jiyu New Material Co., Ltd. was founded in this context. At present, the newly-built Jiyu 2,2-dimethylol butyric acid production workshop has reached 1200 tons/year, and the 2,2-dimethylol propionic acid production workshop has reached 3500 tons/year. Jiyu company is determined to revitalize China's 2,2-dimethylol butyric acid and 2,2-dimethylol propionic acid industry, and make its due contribution to China's water industry and environmental protection industry.

2019/09/20