News

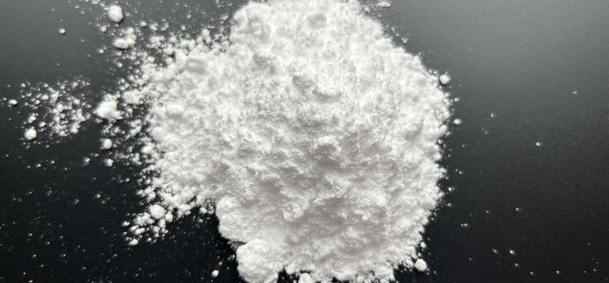

Carboxylic acid type hydrophilic chain extender DMBA and DMPA

Release time:

2019-09-20

1. Foreword

In the production of waterborne polyurethane, carboxylic acid, as an anionic hydrophilic chain extender, is a kind of carboxylic acid with diol, which has been widely used for its unique molecular structure and excellent product performance.

The carboxylic acid type chain extender mainly includes 2,2-dimethylolpropionic acid (DMPA) and 2,2-dimethylolbutyric acid (DMBA), which is a unique multifunctional hindered diol molecule with both hydroxyl and carboxyl groups; increase the alkali solubility of the coating. Can be applied to water-soluble polyurethane systems, water-soluble alkyd resins and polyester resins, epoxy ester coatings, polyurethane elastomers and powder coatings.

It can also be used in leather materials, liquid crystal, ink, food additives and adhesive chemical industry, etc., especially in the manufacture of water emulsion polyurethane and leather finishing agent, it is not only a chain extender, but also can make polyurethane get good self emulsifying performance, can greatly improve the stability of polyurethane water emulsion, so it is widely used.

Superiority of 2. use of dimethylol carboxylic acid

Aqueous polyurethane emulsion usually introduces hydrophilic agent into polyurethane molecular chain, then neutralizes with alkali to form salt, and then disperses in deionized water by mechanical stirring to form polyurethane aqueous emulsion.

Applied to waterborne polyurethane hydrophilic agent mainly has three types of anion, cation and non-ion. Anionic type mainly includes: 2,2-dimethylol propionic acid, 2,2-dimethylol butyric acid, tartaric acid, sulfonic acid butanediol, sodium ethylenediamine ethyl sulfonate, half ester synthesized from glycerol and maleic anhydride, etc. Cationic type mainly includes methyl diethanolamine, triethanolamine, etc. Non-ionic type mainly includes hydroxyl-terminated polyethylene oxide.

Non-ionic hydrophilizing agents, such as polyethylene oxide, must be present at high levels to stabilize the dispersion. The water-based polyurethane resin made of hydroxyl polyoxyethylene ether as hydrophilic group has good electrolyte resistance, but the film-forming water resistance is very poor, so it is not practical;

Cationic hydrophilic agents such as ethylenediamine sodium acrylate adduct as a hydrophilic base compound make the whole reaction system alkaline, not only the rapid reaction of-NH2 group and-NCO group, but also the reaction of-NCO and-NHCOO-, so the reaction is difficult to control, easy to gel, and the prepared emulsion particles are coarse, film-forming water resistance is poor, so it can not be used in industry;

Dihydroxymethyl carboxylic acid in the anionic type itself contains two hydroxyl groups and also acts as a chain extender, which makes it show great advantages in the preparation of self-emulsifying PU emulsion. In the process of carbamate synthesis, it makes the reaction system acidic. Under acidic conditions,-NCO and-OH react mildly, while-NHCOO-does not participate in the reaction and will not cause gel. In addition, dimethylol carboxylic acid also acts as a chain extender, so that the hydrophilic group (I. e. carboxyl group) is located in the macromolecular chain segment, and the tertiary amine can be used as a neutralizing agent to make excellent stability and excellent water resistance and solvent resistance of the film. Waterborne polyurethane resin. Dimethylol carboxylic acid is the best hydrophilic compound widely used in the preparation of waterborne polyurethane resins.

3. 2,2-Dimethylolpropionic Acid (DMPA) and 2,2-Dimethylolbutanoic Acid (DMBA)

In these two kinds of dimethylol carboxylic acid, 2,2-dimethylol propionic acid used earlier, is currently more commonly used a hydrophilic chain extender. Although it has many advantages, it still has many disadvantages, mainly its own high melting point (180-185 ℃), it is difficult to heat melting, which requires the addition of organic solvents such as N-methyl pyrrolidone (NMP), N.N-dimethyl amide (DMF), acetone, etc., and NMP has a high boiling point, it is difficult to remove after the preparation of APU. Moreover, the solubility of DMPA in acetone is small, and a large amount of acetone needs to be added in the synthesis process, which not only wastes energy but also brings security risks. Therefore, the use of 2,2-dimethylol propionic acid not only produces high energy consumption, but also easily causes organic residues in the product.

2,2-dihydroxymethyl butyric acid is a new type of hydrophilic chain extender which has emerged in recent years. 2,2-dimethylol butyric acid and 2,2-dimethylol propionic acid compared to the main advantages of the following:

1. Better solubility in organic solvents. The following table shows the solubility data of DMBA and DMPA at different temperatures and different solvents;

Solubility data of DMBA and DMPA in different solvents at different temperatures:

|

Serial Number |

Temperature |

Acetone |

methyl ethyl ketone |

methyl isobutyl ketone |

|||

|

DMBA |

DMPA |

DMBA |

DMPA |

DMBA |

DMPA |

||

|

1 |

20 |

15 |

1 |

7 |

0.4 |

2 |

0.1 |

|

2 |

40 |

44 |

2 |

14 |

0.8 |

7 |

0.5 |

Solubility: unit g/100g solvent

Solubility in water: 48% for DMBA and 12% for DMPA.

2. The reaction rate is high, the reaction speed is fast, and the reaction temperature is low. Such as: synthesis of polyurethane prepolymer reaction time is short, generally as long as 50-60 minutes, and DMPA to 150-180 minutes;

3. Used for waterborne polyurethane emulsion with finer particle size and narrow distribution;

4. low melting point, 108~114 ℃;

5. The diversity of the formula can reduce the use of solvents, thereby reducing the cost of solvents and reducing the cost of waste liquid treatment;

6. Can be used to prepare completely solvent-free polyurethane, polyester system;

In the actual synthesis process, it does not need to consume a little solvent, and the emulsion has good performance and excellent mechanical properties of the adhesive film, which not only shortens the reaction time, reduces energy consumption, but also saves energy. Therefore, 2,2-dimethylol butyric acid is currently known to have the best performance of hydrophilic compounds, industry experts believe that dimethylol butyric acid is a green chemical that will replace dimethylol propionic acid.

Development of 4. Dihydroxymethyl Carboxylic Acid in China

The development and production of 2,2-dimethylol propionic acid in China started late. This is mainly restricted by the process of waterborne resin in China. China started the industrial production of 2,2-dimethylol propionic acid in 1995. In the 21st century, the demand for 2,2-dimethylol propionic acid increased year by year, and formed a certain market scale. However, it is a pity that the production of 2,2-dimethylol propionic acid in my country has not formed a scale so far. There are few manufacturers still producing 2,2-dimethylol propionic acid, and the production scale is relatively small. At present, my country's use is mainly dependent on imports.

Because of its complex production process, difficulty in industrialization, high production cost, high price and serious environmental problems, the production development and application of 2,2-dihydroxymethyl butyric acid are greatly restricted. The production of 2,2-dimethylol butyric acid in China began in 2006. There are only a few manufacturers, but all of them have been shut down one after another due to the above reasons. As a result, there is no 2,2-dimethylol butyric acid available in China in recent years, resulting in many water-based material manufacturers crying for food. They are eager to change this passive situation as soon as possible and hope to use 2,2-dimethylol butyric acid as soon as possible.

Jiangxi Jiyu New Material Co., Ltd. was founded in this context. At present, the newly-built Jiyu 2,2-dimethylol butyric acid production workshop has reached 1200 tons/year, and the 2,2-dimethylol propionic acid production workshop has reached 3500 tons/year. Jiyu company is determined to revitalize China's 2,2-dimethylol butyric acid and 2,2-dimethylol propionic acid industry, and make its due contribution to China's water industry and environmental protection industry.

Next Page

Next page:

Share