News

Preparation method of 2,2-dimethylol propionic acid

Release time:

2020-09-19

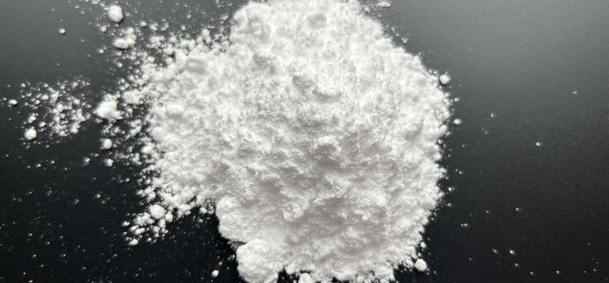

In view of the shortcomings in the prior art, the present invention provides a method for preparing 2,2-dimethylol propionic acid (DMPA). The method steps described are as follows:

Step 1: Condensation

Water, 37wt% formaldehyde and activated carbon-loaded sodium hydroxide are added into the condensation reactor, 99wt% n-propionaldehyde is added dropwise during stirring, and after the addition is completed, the condensation reaction is maintained at 20-60 ℃ for 6-14h; The condensation product is filtered and neutralized by adding 85wt% formic acid to a PH value of 6-7.2, and then transferred to an oxidation kettle. The molar ratio of 37wt% formaldehyde and 99wt% propionaldehyde was 2.2-2.7: 1, the mass ratio of water and 37wt% formaldehyde was 0.8-1.2: 1, the mass ratio of activated carbon loaded sodium hydroxide and 99wt% propionaldehyde was 0.05-0.1: 1, and the mass ratio of 85wt% formic acid and 99wt% propionaldehyde was 0.03-0.05: 1.

Step 2: Oxidation

The materials in the oxidation kettle are distilled to recover unreacted formaldehyde, then the temperature is raised to 60 degrees C, 35wt% hydrogen peroxide is added dropwise during stirring, and the oxidation reaction is maintained at 60-90 degrees C for 6-10h after the addition is completed; water is added to the oxidation product for distillation to remove formic acid. The crude 2,2-dimethylol propionic acid obtained by concentrating the oxidation product until the water content is between 5wt% and 8wt%, and cooling crystallization and centrifugal separation; the molar ratio of the 35wt% hydrogen peroxide to 99wt% n-propionaldehyde is 1.1-1.5: 1; and the dilute sulfuric acid solution is prepared from 98wt% sulfuric acid and water according to a ratio of 1: 11.

Step 3: Refining

Dissolve the crude 2,2-dimethylol propionic acid with water with a mass ratio of 1:1, raise the temperature to 50-60 ℃ under stirring, add iron removal agent and activated carbon, filter after half an hour to remove activated carbon; Concentrate at atmospheric pressure to a water content of 25wt%~ 30wt%, discharge the material, cool the crystal, and then centrifuge, dry and sieve to obtain the 2,2-dimethylol propionic acid product.

Step 4: mother liquor recovery

The crude mother liquor is re-concentrated and then recrystallized, and 2,2-dimethylol propionic acid is recovered again; the high-quality mother liquor is concentrated, decolorized, crystallized, centrifuged and dried to recover 2,2-dimethylol propionic acid; the high-quality mother liquor is recrystallized and the mother liquor produced for the second time is returned to the crude mother liquor for recycling.

The beneficial effects of the present invention: the present invention uses activated carbon-loaded sodium hydroxide condensation catalyst instead of inorganic alkali, which can stabilize the pH value, improve the reaction rate and condensation yield; add water to remove formic acid, reduce the impact on the product yield, facilitate dehydration and reduce mucilage, and crude products Easier to crystallize, pure crystals, large particles, easier centrifugal separation, and high filtration efficiency; use water as a diluent instead of chemical solvent refining, save cost, no organic solvent is used in the crystallization process, with low energy consumption and good working environment in the crystallization and centrifugation processes. Adding iron remover and activated carbon is beneficial to improve product quality. The crude mother liquor is re-concentrated and then recrystallized to extract the product again. The fine mother liquor is then concentrated, decolorized, crystallized, centrifuged and dried to recover 2,2-dimethylol propionic acid again, thus improving the product yield; the refined mother liquor is recycled and returned to the crude mother liquor, with less wastewater discharge, which is conducive to clean production.

Previous Page

Share