News

Waterborne Coatings Trends

Release time:

2020-03-13

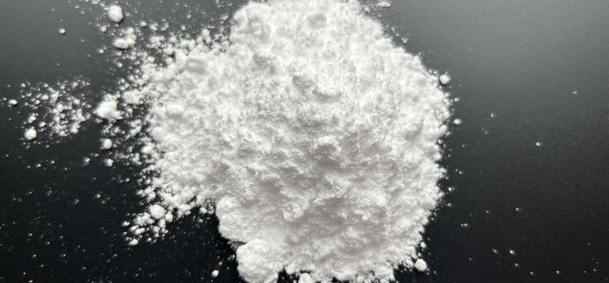

It is understood that before 2005, only Japan Asahi Kasei Co., Ltd. had the ability to industrialize the production of 2,2-dimethyl butyric acid (DMBA). In 2005, after Asahi Kasei stopped production, it transferred its technology and equipment to Pasto, Sweden, the world's largest polyol manufacturer. As Pasto is the only manufacturer of DMBA at present, all the products needed in China are imported, so the import price of this product is as high as 120000 yuan/ton.

DMBA solves the problems of dimethylol propionic acid (DMPA), which is widely used in polyurethane coatings, such as adding organic solvent, high melting point, slow dissolution rate, long reaction time, high energy consumption, poor product performance and large amount of residual solvent. The waterborne polyurethane produced with DMBA as an internal emulsifier does not need to use organic solvents, so the organic residue is zero, and the product coating film is more uniform and has good water resistance. DMBA is therefore regarded as a new generation of green environmental protection chemicals for waterborne polyurethane. A few days ago, the technology has passed the appraisal organized by the Jiangxi Provincial Science and Technology Department.

Water-based coatings to replace the traditional solvent-based coatings has become a major trend in the development of coatings, with the gradual improvement of environmental standards, the amount of water-based coatings is growing at a faster rate, water-based polyurethane production of DMBA demand is also growing. DMBA is not only the key raw material of water-soluble polyurethane, but also an important raw material for the production of polyester and epoxy resin. Mr. Li Xianming, chairman of Jiyu Chemical, has gone to sea many times to discuss technical improvement with foreign friends and achieved remarkable results.

Next Page

Share