Technical Information

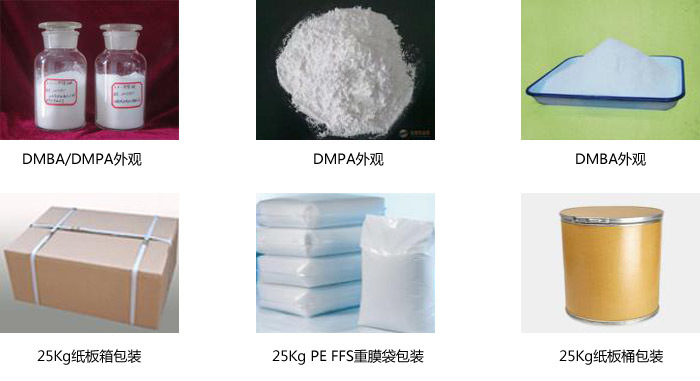

DMBA and DMPA product appearance and packaging pictures

Both DMBA and DMPA are odorless, free-flowing white crystals. Product packaging for 25Kg specifications. Usually the factory packaging is PEFFS heavy film bag packaging, or cardboard box packaging. Can also be packaged according to customer requirements. ▲ The reference size of each package shall be subject to the actual delivery by the user: PEFFS heavy film bag: cardboard box: (length) 380mm × (width) 380mm × (height) 330mm; Cardboard barrel: (diameter) 350mm × (height) 430mm.

2019/09/20

Good news (our DMPA and DMBA are now available in large quantities)

Warmly celebrate the successful production of 2,2-dimethylol propionic acid (DMPA) of Jiangxi Jiyu New Materials Co., Ltd. in January 2018. From safety, environmental protection, production management to fully meet the design level, product quality indicators fully qualified. The production of 2,2-dimethylol propionic acid (DMPA) makes up for the current supply of imports (GEO in the United States and Pasto in Sweden). At the same time, it also meets the needs of our DMBA customers and solves the single problem of the product! Further improve our domestic and foreign market competitiveness. Welcome new and old customers to visit our company, inspection, guidance, we will continue to provide you with better products and services.

2019/09/20

Waterborne Anticorrosive High Temperature Coatings in Modern Industrial Anticorrosive Work

Water-based high-temperature anticorrosive coatings make new achievements in modern industrial anticorrosion, high temperature resistance, advanced technical content, good anticorrosion and corrosion resistance, and meet the high requirements of modern industry for anticorrosion, temperature resistance, wear resistance, environmental protection, and other technical requirements. The requirements of modern industrial anti-corrosion, environmental protection and energy saving are improved, but with the development of industrial technology, corrosion and anti-corrosion problems are common in petrochemical, energy, power, metallurgy, aerospace and other fields, and the material loss is serious, which affects the continuous production of industry. Beijing Zhisheng Weihua Chemical Co., Ltd. caters to the needs of the market, research and experimental development of inorganic polymer anti-corrosion coating technology in advance, become the highlight of the anti-corrosion industry technology, and has a unique

2019/09/06

Anti-corrosion and corrosion resistance involve various fields of modernization, large industrial and mining enterprises: chemical, petrochemical, steel and large-scale mine smelting pipelines, storage tanks, equipment, etc.; important energy industries: natural gas, oil pipes, oil tanks, power transmission and transformation, nuclear power equipment And coal mines, etc.; modern transportation: bridges, ships, containers, trains and automobiles, etc.; emerging marine engineering. Offshore facilities, coastal and bay structures and offshore oil drilling platforms. Anti-corrosion is to take various means to protect metal objects that are easy to rust, to achieve the purpose of extending its service life, usually using physical anti-corrosion, chemical anti-corrosion, electrochemical.

2019/09/06

Research Progress of Waterborne Polyurethane Plastic Coatings

With the rapid development of the plastics industry, plastic products are widely used in all walks of life and become one of the indispensable materials for the national economy and national defense construction. However, the plastic itself is not ideal for environmental aging resistance such as ultraviolet light, and various defects are often produced on the surface during the processing and molding process. Therefore, surface coating is required to give the plastic a special color or a certain luster, and cover the plastic surface. The flaws make it have a more attractive appearance [1-2]. Plastic coatings include ordinary plastic coatings and engineering plastic coatings. For polystyrene products, polyester film products, organic glass products and other ordinary plastics, can be given.

2019/09/06

Functionalization and waterborne are the development trend of coatings industry

With the improvement of the level of economic development and science and technology, people's requirements for life have gradually increased. In recent years, there have been continuous cases of diseases caused by decoration. For home decoration necessities, coatings are also undergoing innovation. People are no longer satisfied with aesthetics., More inclined to its environmental protection and functionality to meet people's health, environmental protection and aesthetic needs. To the functional development of the current should be in addition to fire prevention, anti-virus, insect, insecticidal, thermal insulation and other existing low-quality functional coatings to increase efforts, scientific research, but also should step up research and solve the difficult, new problems in building decoration. Composite technology will be to improve and meet.

2019/09/06